.

The company Tsakalos Diesel Systems with many years of presence in the field of diesel engines provides complete solutions in terms of oil pumps and turbines.

After 40 years of experience in the field of Diesel, we continue to create a modern test bench for oil and beetle pumps at 71 Filiki Etairia in Volos.

State-of-the-art equipment for repairing beakers, pumps

diesel and turbo engines in combination with the love and years of experience with the subject, make up the image of a complete product rebuilding unit for every diesel engine.

With consistency and know-how, the oil pump test room TSAKALOS SYSTEMS DIESEL, following the latest oil pump technology, has developed an area with excellent equipment, ready to find the solution to every problem of supplying every diesel engine.

SERVICES

CLEANING OF OIL INJECTORS AND OIL INJECTOR PUMPS

Cleaning is essential for proper measurement of the control.

We disassemble the component and then place them in special ultrasonic machines, where the perfect cleaning will be done.Then after the components are ready for assembly with the help of special equipment, the settings defined by the manufacturer are made, which determines the correct operation and therefore the correct measurement of the control that will follow.

The inspection of the oil pumps is done with the appropriate machines which follow the protocols of each manufacturer

Machinery

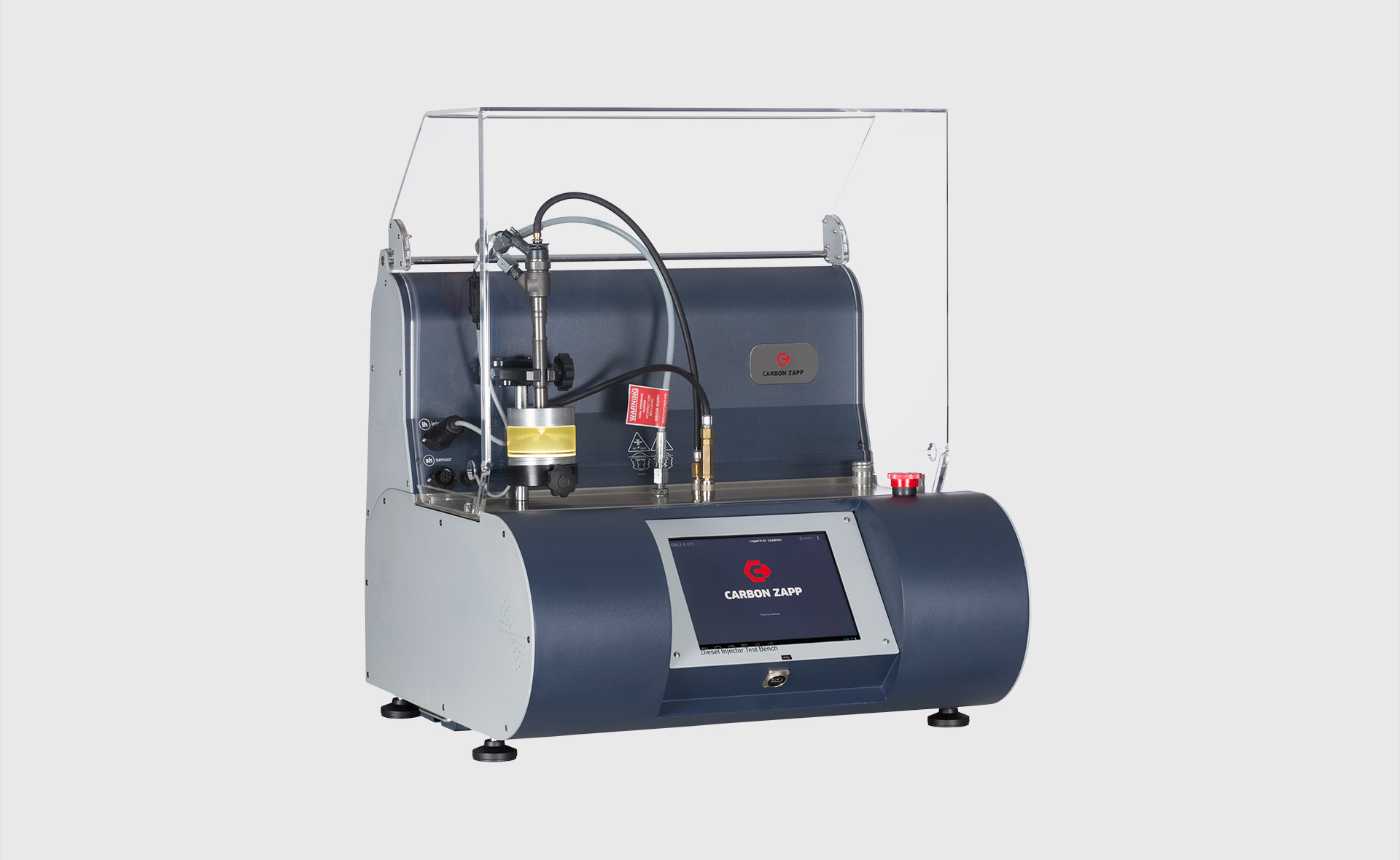

For common rail repair

- CARBON ZAPP MTBR

- CARBON ZAPP CRU2

For the control of BOSCH pumps (VE, PE, VE-EDC)

- BOSCH EPS

For Delphi control ( DPA, DPS, DP200, DPC) DENSO VE and STANADYNE

- HARTRIDGE

- BOSCH EPS

OIL INJECTOR REPAIR

After the check of the injectors has been done, with the measurements we have, we proceed to the repair process. The official equipment in our diesel systems offers us the possibility for a reliable result. The injector is swept with special presses inside, measuring its internal dimensions, which then determine the adjusting washers required to achieve the perfect quantity setting.

The final assembly is done with special tools for proper tightening at all points of the injector. When the repair is completed, we reposition the injector in the special test bench, thus checking the previous repair.

Finally we print the measurements, which certify the correct operation

of the sniffer.

The repair is done only with original spare parts and a warranty is provided

PUMP REPAIR

After cleaning and testing the pump, we proceed to its repair, following all the necessary procedures for its complete reconstruction. Finally, we reposition the pump in a special test bench, for the certification of good operation and print the control measurements.

The repair is done only with original spare parts and a warranty is provided.